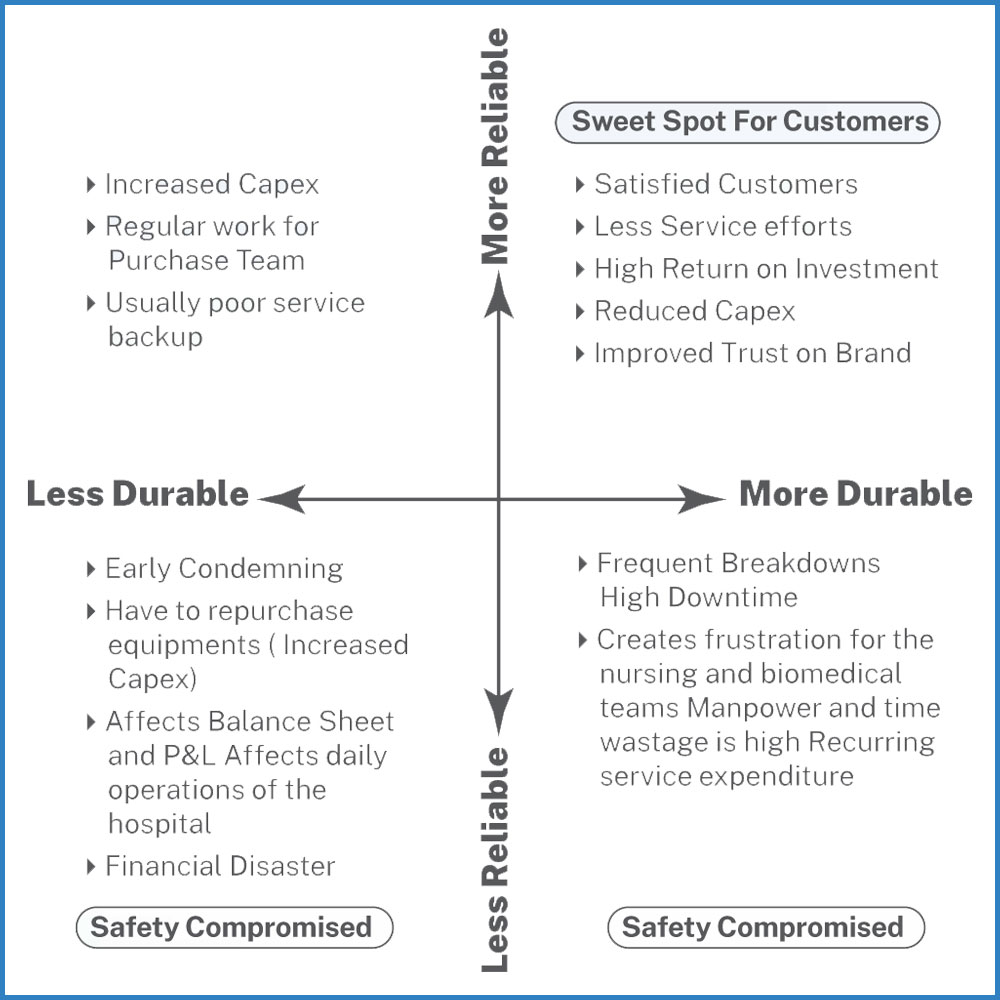

Reliability is defined as the mean time to first failure.

This dimension reflects the probability of a product malfunctioning or failing within a specified time period. Among the most common measures of reliability are the mean time to first failure, the mean time between failures, and the failure rate per unit time. Because these measures require a product to be in use for a specified period, they are more relevant to durable goods than to products and services that are consumed instantly.

Reliability normally becomes more important to consumers as downtime and maintenance become more expensive. Hospitals, for example, are especially sensitive to downtime during the monsoon seasons as patient flow increases. Reliable equipment can mean the difference between life and death.

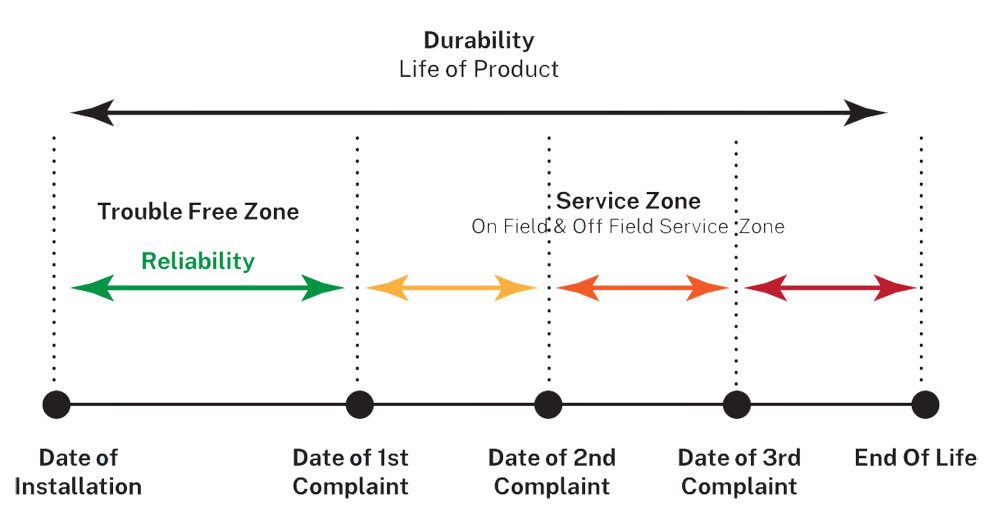

Durability is defined as the life time of the product.

A products durability is fixed based on the time until it is no longer economical and safe to operate it. This happens when the repair rate and the associated costs increase significantly.

For a syringe/ infusion pump if failures happen once in a year it is assumed as it is not economical and safe to operate the same. This can happen after 7 to 10 years or after the durability hours as mentioned in the table above.

Biomedical engineers must weigh the expected cost, in both price and personal inconvenience, of future repairs against the investment and operating expenses of a newer, more reliable model. Durability, then, may be defined as the amount of use one gets from a product before it breaks down and replacement is preferable to continued repair.