Syringe and volumetric infusion pumps are the most used electronic gadget/apparatus in any hospital. Say a 200 bedded hospital with 50 ICU/CCU beds can use anywhere between 100 to 200 pumps. Even patient monitors will not be more than 60 or 70 Nos in such a hospital. As the number of pumps are very high the same has to be tracked regularly to ensure they are secure.

Syringe and Volumetric infusion pumps are the maximum transported electrical gadget in any hospital. As pumps are therapeutic equipment delivering critical/toxic drugs requiring continuous infusions, they have to be transported along with the patients many times. The pumps will be moved from Operating Rooms to Post Operative wards, or Emergency Rooms to ICUs, ICUs to wards or other ways. As the pumps are transported, their ownership and responsibility cannot be tied up with the particular department or section. There is always a chance of missing them temporarily or permanently.

Pumps are also moved between beds in an ICU. They are kept in cupboards when not in use. They are missed inside the cupboards or shelves. When needed they will not be found. One department will be running short of pumps and another department will keep the pumps in the shelves in idle condition.

As the count of pumps is high in the hospital the maximum number of not working machines in the Biomedical Engineering department is also pumps. As the number of not working pumps are high and are of multiple brands, the Biomedical department lacks the expertise to service them. There by the hospital Biomedical relies on the vendors to service the pumps. The pumps are handed over to the vendors which have to be tracked responsibly to collect it back. When a patient gets transported to another hospital, the pumps are moved in the ambulance. There by again the pumps have to be tracked to get them back.

The value of each pump is less than USD 800 and hence the cost of tracking should not exceed say USD 50, otherwise it is not worth the cost. The collective cost of all pumps will total to very high value but the individual cost is low. This poses a challenge to track them at lower cost. There are asset tracking systems in the market costing USD 150 to USD 200 with complex software. This is not suitable for pumps as the cost of tracking cannot be disproportionately a high cost when compared to the cost of pumps

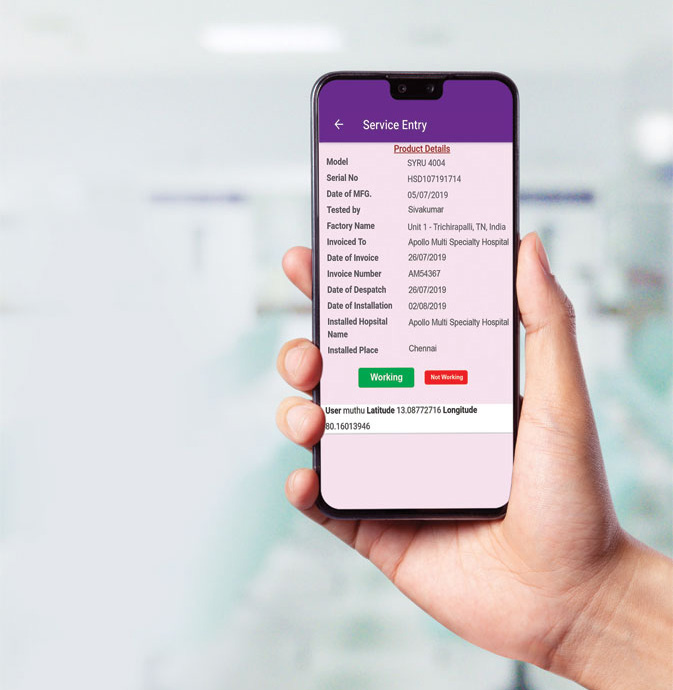

AKAS pumps are pasted with a QR code sticker. This makes it easy for scanning with an application software provided by AKAS. An android mobile can be used to scan the QR Code stuck on the pump. At the time of scanning the pumps the GPS location is captured thereby location specific to approximately 5 to 10 metres is captured. The distance accuracy depends on the mobile instrument used and this accuracy is improving with latest models of mobile phones. Thus the ICU name or OT or ward where the pump was scanned is recorded. The time, date and the person capturing the machine at the particular GPS location is all recorded. The Biomedical engineer in the hospital is normally responsible to scan all AKAS pumps with the mobile application, every month. If any machine is not scanned for more than 30 days a report of un-scanned pumps can be generated and viewed. This will help the Biomedical department to track the particular pump from the last verified physical location. Thus every 30 days all pumps are scanned / located and physically inspected.

This becomes a habit in the BioMedical Department and the assets are always tracked.If a pump is missed scanning for more than 60 days this can be escalated to the next level of management. This will ensure the pumps are scanned by the Biomedical department periodically. Now there is no question of pumps getting lost or missed. A pump which is kept in a cupboard in an ICU unutilized for months together is as good as a pump which is lost. If the pump is not located when it is needed then what is the point in having one. If a pump is missed in the scan, the last scanned location is available with which we can investigate which department it was found last. This can help further tracking or investigation. Continuous tracking or real time tracking (like vehicle tracking) is more complicated and more expensive. It can suit high value goods on the move, but not pumps which are lower value. Hence AKAS solution of simple QR code with GPS location is the most effective way to asset track a pump. AKAS pumps come with default QR Code sticker pasted. There is no extra cost for the customer. The software is also free to track the pumps.

Complaint registration for failed pumps are also through the QR code scanning. So the down time starts from the time of scanning and clicking as not working. There is no hassle of calling the company service department, getting unreturned calls, etc. Just scan and click NOT WORKING. The company service engineer is now bound to attend to the complaint as quick as possible. At the end of a year we can calculate the down time for the pumps supplied.

Asset utilization is another benefit for the hospital. Utilization of pumps based on used hours can be identified in each department or ICU etc. This can help identify which department is short of pumps and which department is having excess of pumps. This will help optimize the number of pumps. The life of the pumps does not depend only on the years since installation, it is based on the hours / days of use also. This can be tracked with the QR code scanning. The pumps used for more hours and less hours can be swapped locations to manage uniform utilization. As an example if a pump will face end of life at 15000 hours or 10 years from installation, then we have to ensure all pumps run 15000 hours of use within the 10 years of life. The utilization is poorly managed if a pump sparingly used at 3000 hrs completes 10 years of life, where as another pump crossed the 15000 hrs mark in 5 years.

AKAS pumps are equipped with QR code stickers and mobile android software which can help track the pumps GPS location and ensure the pumps are verified periodically. This can ensure pumps are not missed and assets are intact. This comes free with all AKAS pumps.