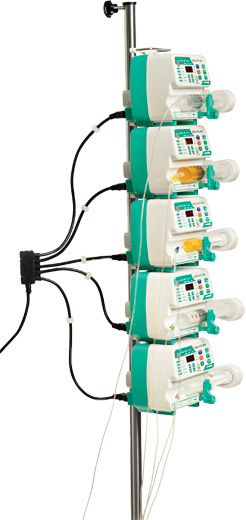

Today it is required to use multiple syringe infusion pumps on a single bed. Multiple drugs are infused continuously for the patient at the same time. Some drugs are infused intermittently once in a few hours. Thus we see even 10 pumps stacked for a single patient, either in a single stand or in 2 stands/IV poles.

Earlier there were hardly 1 or 2 pumps used on every bed and the trend has changed to using multiple infusion and syringe pumps on a single patient. However, many issues/challenges arise with its use, including a workload increase for nurses. Some other major challenges associated with multiple syringe infusion pumps are:

Today, more than 8 to 10 pumps are placed per patient instead of the earlier trend of 1 or 2 pumps per bed. The ICU sizes are the same and so are the number of beds in the ICU. So, when more pumps are squeezed near the patient, it causes poor access to the head side of the patient Moreover, the most commonly used pumps have a significant size. This size did not matter when only 1 or 2 pumps were used. However, the size becomes a constraint with a large number of pumps. Thus, it will be easy to use multiple pumps if the pumps are small. AKAS pumps are smaller occupying only 2.2 litres of space. Most of the pump manufacturers do not bother about this factor, and their pumps hold 4 to 6 litres of space.

A female nurse can comfortably use the pump at a maximum height of 155 cm, and the lowest height of 65 cm. So, there is only 90 cm of space available to place any number of pumps. Thus, the maximum height of each pump should be less than 14 cm, so that approximately 6 pumps can be set in a stand.

Pumps are normally transported from OT to Post-operative wards, between ICUs, between wards. Pumps are also transported along with the patient for CT scanning, X-rays, Ultrasounds, etc. Pumps are also fixed on demand and are shifted from bed to bed depending on the needs. When more pumps are used more they are transported. Most of the nurses are females and cannot handle much of physical work load. So it is necessary that the pumps are light weight and easy to carry. The lesser their weight the better it is. Generally, most and many other pump manufacturers do not give much priority to the pump weight, resulting in heavy pumps weighing around 2.4 to 2.7 kg. However, AKAS understands the importance of lower weight pumps, and thus manufactures pumps that are less than 1.75 kg in weight.

"AKAS understands the importance of lower weight pumps, and thus manufactures pumps that are less than 1.75 kg in weight".When 8 to 10 pumps are needed on a bed, the need for power sockets goes many folds up. There are patient monitors, defibrillators, ventillators all of which need power sockets. Pumps take up the maximum number of sockets. Running multiple power chords for pumps gives a bad appearance and creates a confusion to trace the power chords.

So these days pumps come with a docking station where a single power chord can be used to power the docking station and the docking station in turn supplies power to the 4 or 5 pumps in the station. This docking station is very expensive. At AKAS a simple 5 in 1 power chord is provided where one power chord splits into 5, to supply power to 5 pumps. This is a simple cost effective solution. This serves the purpose in total, with out necessity to complicate the matters.

The load on the generator or the UPS increases with the increase in the number of equipment. Most of the pumps consume 15 to 18 VA power. So, if 6 pumps are used per bed on an average, the power demand reaches around 100 to 120 VA per bed. This, in turn, enhances the load on the generator because many pumps are used per bed. AKAS pumps consume only 7 VA power and thereby puts only 50% load on the generator compared to the pumps from other manufacturers.

The workload on the nurses increases substantially due to an increased number of pumps per bed. When 4 to 5 pumps are running, trying to fix an extra pump becomes a big task for the nurses. The resultant activities like finding a new stand, trying to get a power socket freed up or using extension power sockets pose additional challenges before these nurses.

Tasks like diluting drugs with the right diluting agent, labelling and, refilling them put an additional load on the nurses. Moreover, each pump gives an alarm due to multiple reasons like occlusion and to signal the end of infusion. These alarms also require the attention of the nurses. To tackle such challenges, it is essential to properly train nurses in the efficient operation of pumps, which, in turn, would help to reduce their workload.

The need to multitask increases the cognitive load on the attendants, which results in mistakes. The errors get noticed while they offer their therapeutic services and come across as medication errors. Thus, the increase in cognitive loads ultimately results in significant medication errors.

For this reason, it becomes paramount to reduce the nurse’s cognitive load in every possible way. One such solution involves using pre-printed drug labels with an International standard colour coding. This will not only help the nurses to identify the drug that is infusing from a distance, but also prompts quick attention for specific/toxic drugs.

Multiple drug delivery lines to a single patient can also cause complications and time issues while tracing each route every time. At AKAS, we offer a tubing organizer for the nurses to channel the tubing at the machine end, and the patient end. The use of this organizer will significantly reduce the tracing time of the delivery lines.

When there is a rise in the number of pumps per bed, it becomes mandatory to address multiple issues associated with them. Therefore, by considering all the problems mentioned above, the outcome for the patients as well as the medical staff would show a drastic improvement.